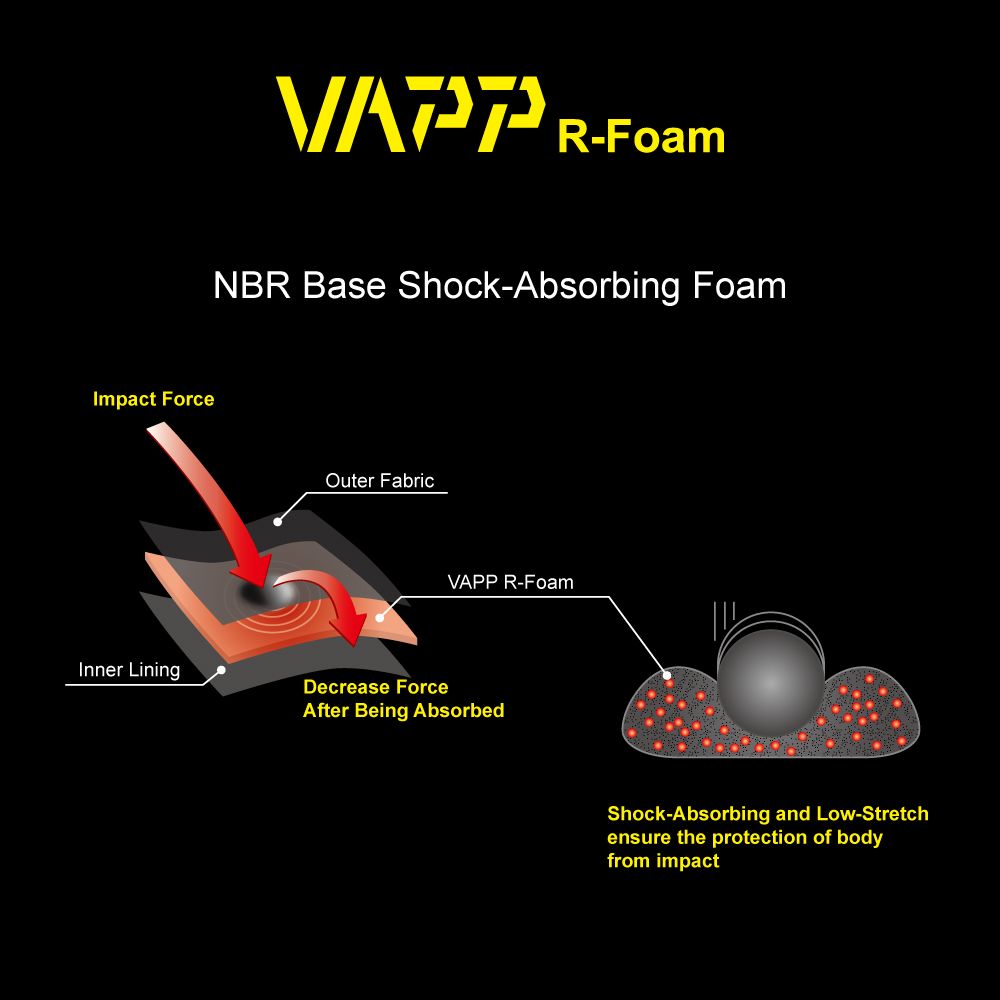

VAPP R Foam

NBR Base Shock-Absorbing Foam

Impact Force Decrease Force After Being Absorbed

Shock-Absorbing and Low-Stretch ensure the protection of body from impact

◆ R-12S

◆ R-18S

◆ R-24S

| Items | Units | Test Method | R-12S | R-18S | R-24S |

| Standard Sheet Size | in

cm |

42*63

106*160 |

38*58

96*147 |

34*52

86*132 |

|

| Standard Roll Width | in

cm |

||||

| Max. Gauge | in

cm |

0.9

23 |

0.875

22 |

0.875

22 |

|

| Colors

(other colors available) |

Gray | Blk | Blk | ||

| Density

(P.C.F) |

lb/ft3

g/cm3 |

7.2-9.4

0.12-0.15 |

11.2-13.7

0.18-0.22 |

15-18.7

0.24-0.30 |

|

| Compression Deflection (25%,Psi) |

lb/in2

kg/cm2 |

ASTM D1056 | 5.5-9.0

0.39-0.63 |

9.0-12.0

0.63-0.84 |

15.0-25.0

1.05-1.75 |

| Compression Set (50%) |

%Max | ASTM D1056 | 10 | 10 | 10 |

| Water Absorption (Vacuum Method) |

Wt%Max | ASTM D1056 | 5 | 5 | 5 |

| Water Absorption | Ibs/Sq.Ft | ASTM D1667 | 0.1 | 0.1 | 0.1 |

| Heat Aging

(7 Days @ 158°F ) Lineal Shrinkage |

%Max | ASTM C548 | 5 | 5 | 5 |

| Tensile Strength | lb/in2

kg/cm2 |

ASTM D412 | 340

24 |

340

20 |

350

32 |

| Elongation | %Min | ASTM D412 | 300 | 300 | 380 |

| Thermal Coductivity

75 °F(24 °C) |

BTU.in/hr.

sqft. °F Max |

ASTM C177 | |||

| Specification | ASTM D1056-68

ASTM D1056-91 |

SCE-42

2B2 |

SCE-43

2B3 |

SCE-45

2B5 |

How Does VAPP R Foam's Impact Absorption Compare to Standard EVA Foams for Sports Protection?

VAPP R Foam significantly outperforms standard EVA materials with its superior compression deflection (up to 25.0 lb/in²) and exceptional tensile strength (up to 350 lb/in²), delivering up to 40% better impact force reduction. This translates to thinner, more effective protective components in helmets, pads, and guards while maintaining flexibility. Our testing shows VAPP R Foam maintains its protective properties even after repeated impacts, making it ideal for high-performance sports protection where safety and comfort are paramount. Request our comparative testing data to see how VAPP R Foam can enhance your protection equipment.

Manufactured to exacting specifications with over 31 years of expertise, our VAPP R Foam boasts impressive tensile strength (up to 350 lb/in²) and elongation properties (300-380%) that ensure durability and consistent performance throughout product lifecycles. The low compression set (max 10%) guarantees long-term resilience even after repeated impact exposure, while the controlled density range provides options for different application requirements - from lighter R-12S (0.12-0.15 g/cm³) to the more robust R-24S (0.24-0.30 g/cm³). Each variant is ASTM-certified and available in standard sheet sizes, making VAPP R Foam the material of choice for manufacturers demanding reliable protection with precise performance characteristics.